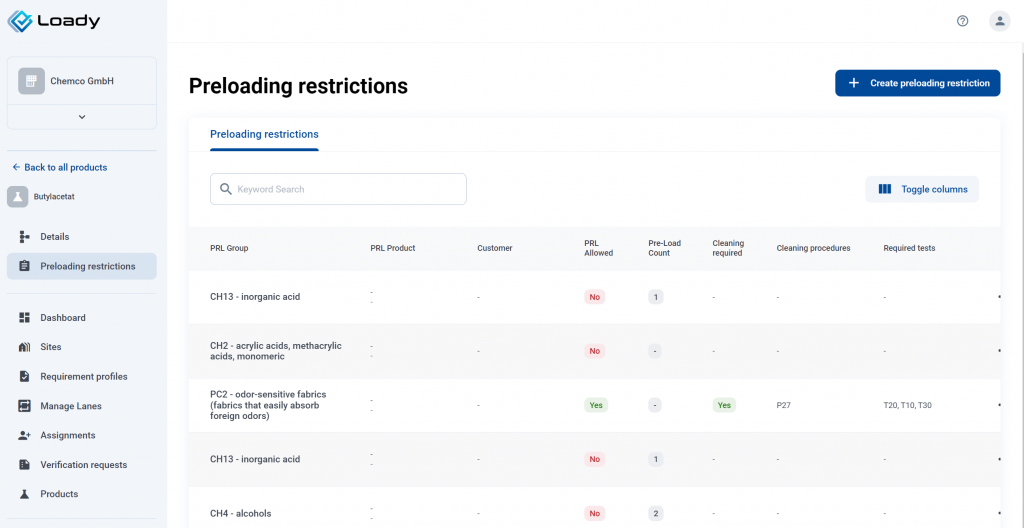

Product quality and safety are essential in all manufacturing industries. Especially in the fields of chemistry, food, pharma, and consumer goods, knowing what substances have been previously shipped, understanding if there are incompatibilities, and ensuring that regulatory requirements are met, is a big challenge. Companies need to apply extremely strict rules in order to ensure high quality and prevent any kind of contamination of their products

The crux of preload restrictions:

- There are many restrictions of different types and depending on different variables

- To specify them you need deep chemical know-how in combination with logistics understanding

- Currently, companies manage these requirements in an unstructured, decentral, non-standardized way

- How to specify pre-load restrictions? In what chemical categories, product families, or classes? Are you supposed to keep endless lists of product names that you exclude?

- Cleaning methods and required certificates depend on the pre-products, but – depending on the substance or its application – they still may vary

- Data sharing with carriers is unstructured leading to enormous efforts spent on analytics of requirements

- Missing standards make it impossible to automate the pre-product checks